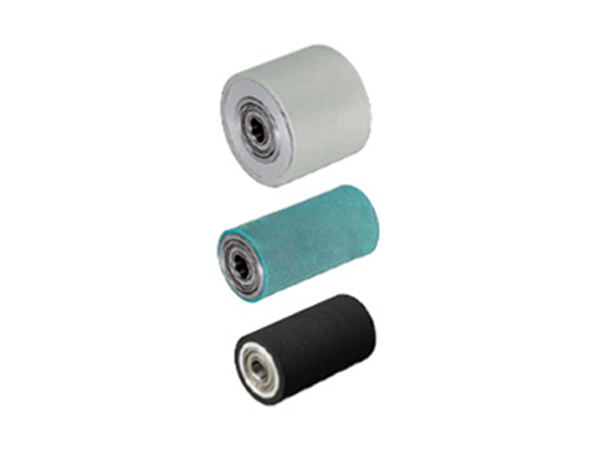

The rubber-coated roller has good wear resistance and does not degummed

The metal is coated with polyurethane elastomer material, made into polyurethane rollers, polyurethane rubber rollers, etc., with good wear resistance. Casting polyurethane rubber rollers are roughly divided into polyester type according to the flexible segment in the polyurethane molecule, and their physical and mechanical functions are high. It has good solvent resistance and is commonly used in non-ferrous metals. Polyether type has good water resistance, low temperature resistance and good process performance. It is often used to make drawing rollers, printing rollers, etc.

The processing requirements of polyurethane coated wheels go through the following process:

1. Cleaning the iron core: if it is a new rubber roller iron core, it is necessary to clean the oil on the surface of the iron core with a cleaning agent; if it is an old rubber roller iron core, it is necessary to remove the encapsulation of the old rubber roller and use it at the same time. The cleaning agent cleans the remaining glue on the surface of the iron core. Rubberized shock-absorbing briquette

2. The surface of the rubber roller iron core is roughened: the surface of the rubber roller iron core is roughened to increase the bonding area between the surface of the rubber roller iron core and the encapsulation.

3. Sandblasting: the rough-treated rubber roller core is sandblasted, and sandblasting will be based on the raw material of the rubber roller core to select different types of sand for sandblasting. Sandblasting is to make the surface of the rubber roller rougher, and the glue and the iron core can be better bonded after encapsulation.

4. Coating: The rubber roller core after the above treatment is coated according to the customer's requirements.

5. Rubber-coated wheel vulcanization: The rubber-coated rubber roller generally needs 12-24 hours of vulcanization time. After vulcanization, the rubber roller core and the rubber-coated rubber will be tightly bonded together.

6. Rubber-coated wheel processing: processing according to the size and shape required by the customer. When some customers have high requirements on the surface of the rubber wheel, they need to use a lathe for processing.

Polyurethane is an elastomer which is a kind of strong polar polymer compound, and has little affinity with non-polar mineral oil. It is hardly corroded in fuel oil and machine oil. Anti-aging, excellent function, with outstanding oxygen and ozone resistance, it is really a good material.

24-hour service hotline

0755-23346172

Mob: 134-2430-7553 (Mr. Li)

Mob: 135-4329-9605 (Ms. Ding)

E-mail: 986107164@qq.com

Add: No. 36, 1st Floor, Building C, Shengfeng Industrial Park, Songgang Town, Baoan District, Shenzhen

Wechat QR Code