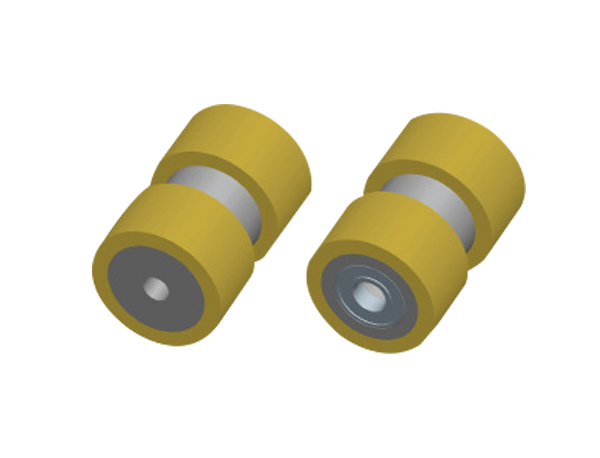

According to the raw materials used in the casters, they can be divided into many types. Among them, polyurethane wheels and rubber wheels are relatively similar, and it is still difficult to distinguish the two from the outside. Then which is better for polyurethane coated wheels or rubber wheels? Next, the editor will give us a brief introduction.

Comprehensive analysis shows that polyurethane wheels are better. What are the reasons? It is mainly reflected in the following aspects:

1. Service life: Polyurethane casters generally have a longer service life and are more wear-resistant, which reduces the operating cost.

2. Load-bearing ability: The load-bearing ability of polyurethane casters is far greater than that of rubber casters, and it is several times or more than the load-bearing ability of rubber casters. Because polyurethane casters have better pits and cracks, they can resist tearing.

3. Environmental protection: Polyurethane is more environmentally friendly. As it is classified as an artificial material, rubber raw materials are not used much.

4. Rolling resistance: As the chemical structure of polyurethane has less rolling friction than rubber, the increased thrust is getting smaller and smaller.

Although in many respects, polyurethane wheels are better than rubber wheels, rubber wheels also have their own advantages, so they have not completely replaced them. For example, rubber casters are soft, comfortable, and good, and they have better cushioning.

The above is all about which is the best polyurethane wheel or rubber wheel, I hope it can be helpful to you.

24-hour service hotline

0755-23346172

Mob: 134-2430-7553 (Mr. Li)

Mob: 135-4329-9605 (Ms. Ding)

E-mail: 986107164@qq.com

Add: No. 36, 1st Floor, Building C, Shengfeng Industrial Park, Songgang Town, Baoan District, Shenzhen

Wechat QR Code